Depth of our technology in preventing failures

Preventing battery fires is a multifaceted challenge due to the many potential triggers and the diverse hazards posed by thermal runaway.

At Core Nova Systems we employ a wide range of complimentary technological elements to provide complete safety solutions.

Preventing Thermal Runaway - An Integrated Systems Approach

-

Battery Management System (BMS)

BMS are electronic devices which monitor the functioning of battery components. They may provide early warning or force emergency shutdown if various aspects of battery performance exceed safe operating parameters.

Core Nova Systems employs a proprietary BMS designed to prevent failures due to uneven distributions of heat or electrical load within a battery pack, a condition commonly arising from damaged connections between cells as a result of accumulated wear and tear.

-

Cooling Technologies

A sufficiently robust cooling system can not only improve battery life and performance, but also play a key role in mitigating the hazards of thermal runaway.

Core Nova Systems utilizes a unique, high-capacity Phase Change Material within our battery packs which not only shuttles heat away from the cells during normal operations, but also supplies unparalleled reactive, targeted cooling to cells in the early stages of thermal runaway to suppress fires and prevent propagation.

-

Internal Barriers

In the case where thermal runaway occurs, it is critical to prevent cascading failures by protecting functional battery cells from the heat and violence of the initial failure. This reduces the total energy released, improving the efficacy of all other safety measures.

An internal barrier material must insulate battery components from both the thermal extremes and abrasive ejecta effects of a thermal runaway event. But it must not add unreasonable mass or volume, or interfere with cooling systems critical for optimized battery performance during typical operation.

Extensive testing and iterative design has informed Core Nova Systems’ selection and implementation of internal barrier materials to achieve these aims.

-

Ruggedized Housing

Many of the causes of catastrophic battery failures originate from without. Therefore the first line of defense must be a sturdy battery housing.

Core Nova Systems’ battery packs are designed to resist external heating, crushing or puncture threats, and the stresses of prolonged vibration.

-

Safe Pressure Release

When a battery undergoes thermal runaway, the intense heat vaporizes the cell’s internal constituent materials. The intensity and rapidity of development of gas pressure is often sufficient to rupture battery housings and project dangerous materials outwards.

Core Nova Systems’ battery packs utilize innovative fail-safe pressure vents to allow for the managed release of gas pressures in the event of a battery failure.

-

Non-Flammable Construction

While Li-ion battery cells are themselves flammable, the rest of the battery pack doesn’t have to be. A non-flammable construction which retains its structural integrity at high temperatures gives peace of mind that internal failures compound to cause further damage to nearby persons or property.

Storage Solutions

Many of the most disastrous battery fires begin in the home while charging unattended in a garage, closet, etc.

The most practical way to add a layer of safety to your e-bike battery is with the CNS Battery Blanket.

Testing for success

Our depth of knowledge and experience in battery testing is the foundation for designing of all our products. Testing for both safety and reliability is paramount to a quality product. Learn more about how we test below:

Thermal Runaway Testing

-

Single Cell Runaway

Single cell tests are performed to characterize how specific cells fail and to determine how consistent those failure modes are. This is useful when selecting cells to use as well as how to configure them from a safety standpoint.

-

Module Level Propagation

In order to characterize how thermal runaway in one cell can affect the nearby cells around it. Factors like cell spacing and interstitial materials can play a role in preventing propagation.

-

Pack Level Propagation

Similar to module level testing, pack level testing is done to ensure that no propagation occurs when one cell is sent into thermal runaway. The main difference is that the final form factor of the battery as well as pressure effects from the battery housing can influence the potential of a propagation event.

Mechanisms to introduce thermal runaway

-

Nail Penetration

This technique involves penetrating a cell with a conductive nail at high speed to quickly short the cell and start a runaway event.

-

Hot Wire

This technique utilizes a nichrome wire wrapped around a cell. Current is run through the wire and the cell is heated at a specified rate. Eventually the polymer separating the anode and cathode melts and the cell is shorted starting runaway.

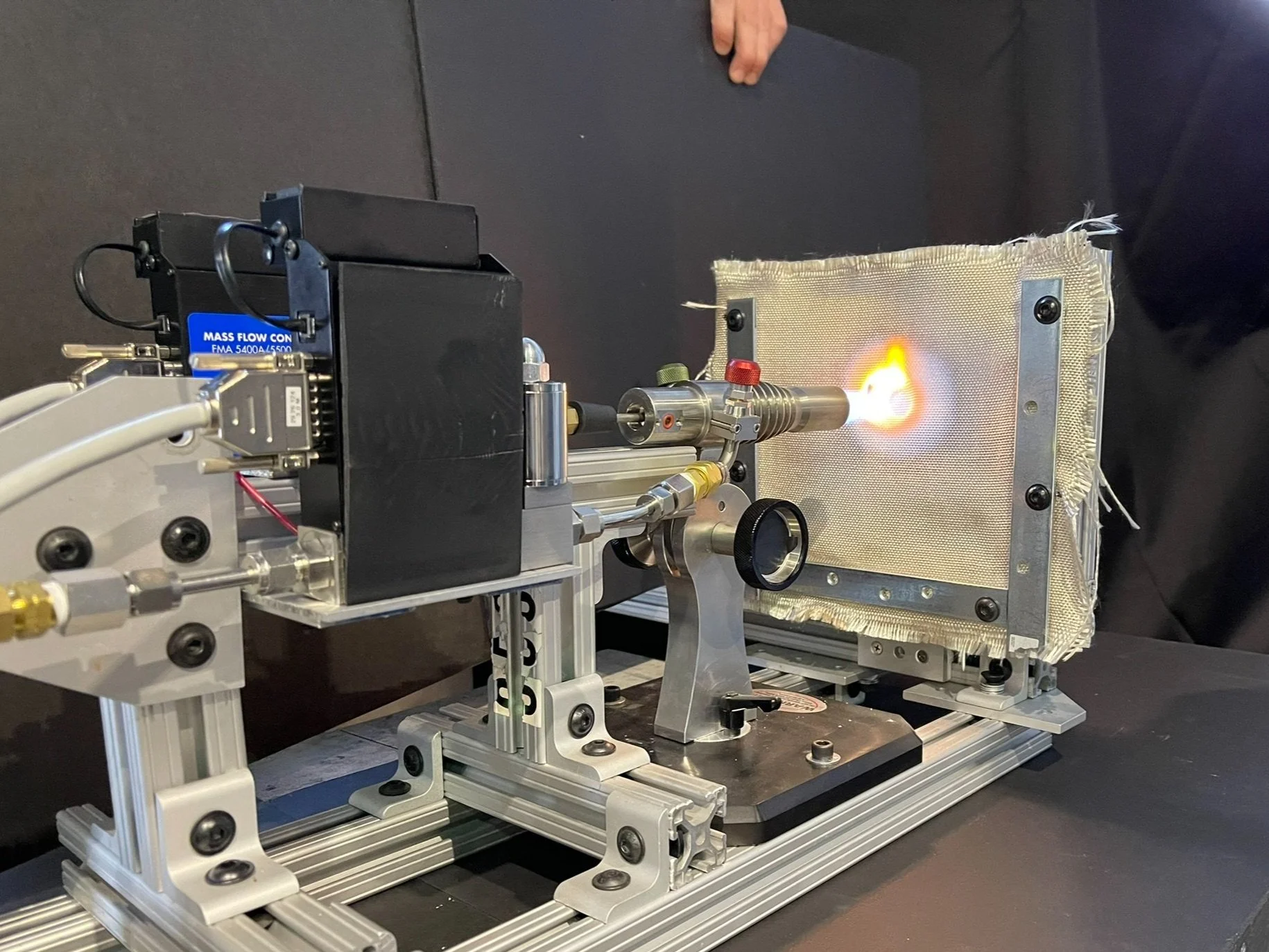

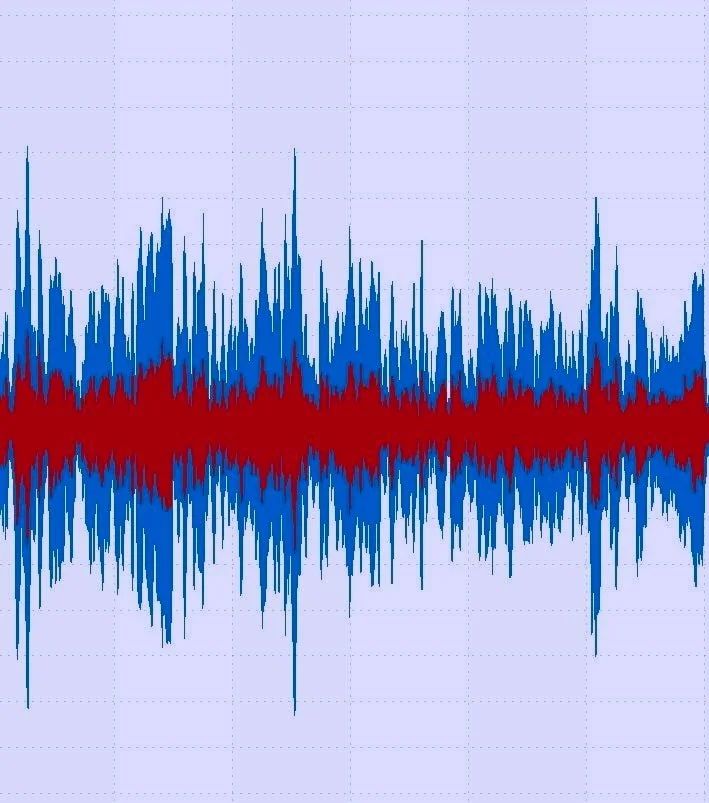

Torch and Grit Testing

The Torch and Grit test is a UL certified testing method that simulates the heat and ejecta from a battery undergoing thermal runaway to determine if a pack’s housing material will hold up to a thermal propagation event. We also use this test method on our Battery Blanket to ensure it is held to the same standard.

Mechanical

-

Shock and Vibration

-

Thermal Cycling

-

Pressure Testing

Electrical

-

BMS Testing

-

Lifecycle Testing

-

Fast Charging